Commercial & Industrial Air Cooler

Constromech FZCO presents wide varieties of Industrial Air Coolers according to different applications. Our Evaporative Air Coolers are best suited in manufacturing facilities, warehousing and storage companies, pharmaceutical industry, animal shelter, food processing units and many more.

Why Us?

We are the pioneer supplier of Evaporative Industrial air cooler in Dubai. With over 19 years of experience, we delivered the best air cooler solutions in and round UAE especially Dubai. From room air coolers to industrial, we delivered wide range of products in the Middle- East.

0

+

0

%

A

A- Graded SME Company in Dubai

What is Industrial Air Cooler?

Industrial Air Coolers are specially engineered and designed for industrial applications that require high degree of cooling and ventilating within closed quarters. The machine is mounted on wheels and can be moved from one place to another easily, after switching off the power supply. It works on the principle of evaporative air cooling; fresh air is supplied continuously through the honey comb evaporative cooling pads where it gets cooled before entering into the space around. Once cooled, the hot air containing impurity and smell leaves the room through exhaust/ ventilation fan at a temperature, leading to a cool/ventilated atmosphere which is clean, healthy and comfortable

Why Air Coolers?

With the rising heat, it is important for you to ensure the productivity of your workers. The products in our Air Coolers range are designed so that your employees can work comfortably and with ease. They not only help in boosting productivity but also offer cost benefits over running a traditional air conditioner all day.

Applications

Manufacturing facilities, warehousing and storage companies, pharmaceutical industry, animal shelter, food processing units, mosques, workshops and other open spaces often experience heat stress in their working environments. They are ideal for these spaces because of their unique ability to provide cooling within tightly enclosed structures by blowing air outwards through a duct or grille system. Our air coolers come with a wide range of accessories to provide end-to-end solutions to customize your cooling needs with enhanced aesthetics.

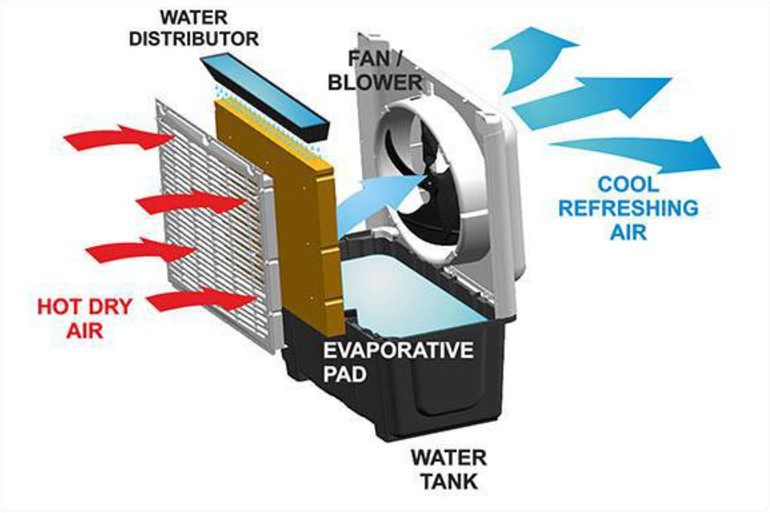

How does it works?

Water drawn from the vertically mounted tank is pumped through the base and up through the evaporative cooler. The evaporative air cooler is made of a card board-like material that absorbs moisture when it comes in contact with air. The moisture evaporates, lowering air temperature. Once its cooled, the air flows into your space.

The most important part in taking care of an air cooler is to know about the components and its function. The cleanliness of these components will determine the efficiency of the air cooler.

Regular cleaning and maintenance of your evaporative air cooler is essential for ensuring that it functions properly and provides cool, clean air. By preventing the growth of bacteria and mold, improving efficiency, prolonging the lifespan of the cooler, ensuring optimal airflow, and improving air quality, you can enjoy the benefits of this cooling system without any of the drawbacks.

It is important to understand that air coolers do not cause colds or other respiratory illnesses directly. Colds and flu are caused by viruses that are transmitted through the air or by direct contact with an infected person or surface. Therefore, using an air cooler does not increase your chances of catching a cold. However, air coolers can have some indirect effects on our health and comfort…

Contact Us

Industrial Air Coolers: The Ultimate Solution for Efficient Cooling

Introduction:

Looking for the perfect cooling solution for your industrial space? Look no further than industrial coolers. With their advanced technology and exceptional cooling performance, industrial coolers are revolutionizing the way businesses maintain comfortable working conditions. In this content, we will explore the benefits of industrial evaporative air coolers and why they should be your top choice for efficient cooling.

Definition and functionality

Air coolers of Industrial type, also known as evaporative coolers, are cooling systems that use the process of evaporation to lower the temperature in large industrial spaces. They work by circulating water over pads or filters, which evaporates and cools the air as a fan blows it into the area. These air coolers are energy-efficient, cost-effective, and provide fresh air circulation, making them a popular choice for cooling industrial settings.

How they differ from traditional air conditioning systems

These are differ from traditional air conditioning systems in several ways:

Cooling Mechanism: They use the evaporation of water to cool the air, while traditional air conditioning systems rely on refrigeration and compression cycles. Evaporative cooling consumes less energy than refrigeration-based cooling.

Energy Efficiency: These are generally more energy-efficient than traditional air conditioning systems. They require less power to operate since they do not use compressors or refrigerants.

Cost: The initial installation and maintenance costs of these air coolers are typically lower than traditional air conditioning systems. They have simpler designs and require fewer components, making them more affordable.

Fresh Air Circulation: It will provide fresh air circulation as they draw in outside air, while traditional air conditioning systems often recirculate the same air within a closed space.

Environmental Impact: They have a smaller environmental footprint compared to traditional air conditioning systems. They do not use ozone-depleting refrigerants and have lower electricity consumption, resulting in reduced greenhouse gas emissions.

Suitability: They are more suitable for dry and arid climates, where the cooling effect of evaporation is most effective. Traditional air conditioning systems can be used in various climates but may struggle to provide efficient cooling in extremely hot and dry conditions.

Overall, they offer a more energy-efficient and cost-effective cooling solution for large industrial spaces, while traditional air conditioning systems are more versatile and can provide precise temperature control in different environments.

Overview of the components and working principle

Components typically include:

- Fan: A large fan is used to draw in air from the outside and circulate it through the cooling system.

- Water Pump: A water pump is responsible for circulating water from a reservoir onto the cooling pads or filters.

- Cooling Pads/Filters: These pads or filters are designed to hold water and provide a large surface area for evaporation to occur. They are typically made of cellulose or other water-absorbent materials.

- Water Reservoir: A reservoir holds the water that is pumped onto the cooling pads.

Working Principle:

- Water Circulation: The water pump circulates water from the reservoir onto the cooling pads or filters. The pads become saturated with water.

- Air Intake: The large fan pulls in warm air from the outside and directs it towards the cooling pads.

- Evaporative Cooling: As the warm air passes through the wet cooling pads, the water evaporates, extracting heat from the air. This evaporation process cools down the air.

- Air Distribution: The cooled air is then blown out by the fan into the desired space, reducing the overall temperature.

- Continuous Operation: The water pump continuously circulates water onto the pads, and the fan continuously draws in warm air, maintaining a consistent cooling effect.

The working principle of these air coolers of industrial type is based on the principle of evaporation. As water evaporates, it absorbs heat from the surrounding air, resulting in a drop-in temperature. By utilizing this evaporation process and a powerful fan, it will provide effective cooling for large industrial spaces while consuming less energy compared to traditional air conditioning systems.

Key Features and Advantages

Evaporative Cooling: It utilize the principle of evaporation to cool the air, which is a natural and energy-efficient process.

Large Cooling Capacity: These are designed to provide cooling for large industrial spaces, warehouses, workshops, and outdoor areas effectively.

Fresh Air Circulation: These coolers draw in outside air and provide continuous air circulation, ensuring a constant supply of fresh air.

Cost-effective: They have lower installation and maintenance costs compared to traditional air conditioning systems. They also consume less energy, resulting in cost savings in the long run.

Environmentally Friendly: They do not use refrigerants or produce harmful emissions, making them environmentally friendly cooling solutions.

Portable and Versatile: Many of them are designed to be portable, allowing them to be easily moved and used in different locations as needed.

Advantages:

Energy Efficiency: It consume significantly less energy compared to traditional air conditioning systems, resulting in lower energy costs and reduced environmental impact.

Lower Operating Costs: The overall operating costs of these air coolers, including maintenance and electricity, are typically lower than those of traditional air conditioning systems.

Fresh and Healthy Air: By drawing in outside air, they provide a constant supply of fresh air, improving indoor air quality and ventilation.

Effective in Dry Climates: They are particularly effective in dry and arid climates, where the cooling effect of evaporation is most efficient.

Simple Installation: These are generally easier and quicker to install compared to traditional air conditioning systems, requiring minimal ductwork or infrastructure modifications.

Low Environmental Impact: With no harmful refrigerants or greenhouse gas emissions, they have a smaller environmental footprint, contributing to a greener and more sustainable cooling solution.

Overall, they offer energy-efficient cooling, cost savings, fresh air circulation, and environmental benefits, making them a preferred choice for cooling large industrial spaces.

Factors to Consider When Choosing an Air Cooler for Industrial purpose:

Several factors should be taken into consideration:

Cooling Capacity: Assess the cooling capacity of the air cooler, which is typically measured in terms of airflow volume or cooling area. Ensure that the cooler can effectively cool the size of the industrial space you intend to use it in.

Climate Conditions: Consider the climate conditions of the area where the air cooler will be used. Evaporative cooling is more effective in dry and arid climates, while its effectiveness may be reduced in humid environments.

Durability and Build Quality: It should be robust and built to withstand the demands of industrial environments. Look for models with durable construction and quality components that can handle continuous operation.

Energy Efficiency: Check the energy efficiency rating of the air cooler. Look for models that are designed to consume minimal energy while providing effective cooling.

Noise Levels: Consider the noise levels generated by the air cooler. In industrial settings, it’s important to ensure that the noise produced by the cooler does not interfere with work or cause disturbances.

Maintenance Requirements: Assess the maintenance requirements of the air cooler. Look for models that are easy to clean and maintain, with accessible filters and pads that can be easily replaced.

Portability and Installation: Determine if portability is a requirement for your air cooler. Consider whether it needs to be easily movable or if a fixed installation is preferred. Also, evaluate the ease of installation and any additional infrastructure requirements.

Cost and Value: Compare the cost of the air cooler with its features, performance, and durability. Consider the long-term value and potential energy savings the cooler can provide.

Brand Reputation and Support: Research the reputation of the brand and manufacturer. Look for reputable companies that offer reliable products and provide good customer support and after-sales service.

By considering these factors, you can choose an air cooler that best suits your industrial cooling needs, provides efficient performance, and offers long-term durability and value.

Conclusion:

When it comes to efficient cooling for industrial spaces, these coolers are the optimal choice. With their impressive cooling capacity, energy efficiency, and low maintenance requirements, they offer numerous advantages over traditional cooling systems. By investing in heavy-duty air cooler, you can create a comfortable and productive environment while reducing energy costs and promoting sustainability. Upgrade to large air cooler today and experience the transformative power of advanced cooling technology.